Diaphragm pumps can be used in a large variety of applications.

Diaphragm pumps are most often used to pump chemicals or other aggressive fluids,

which is why it is incredibly important to select the right materials for your diaphragm pump in order to prevent leakage.

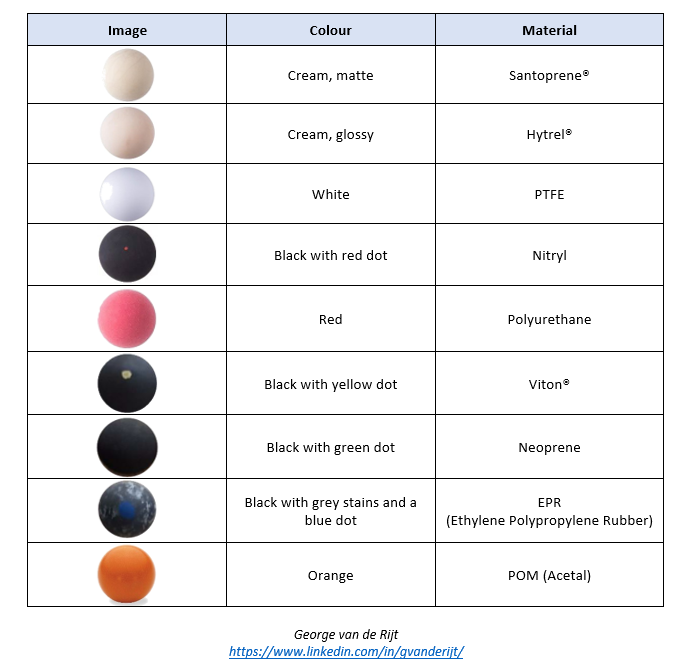

Sometimes however, it is hard to know which materials have been used in the pump.

This could be due to the serial number not corresponding with the materials that have been used inside of the pump.

The best reference point for making a right selection of materials would be to check the fluid that is being circulated within the diaphragm pump.

Therefore we have selected the most common colour compositions below, so that these materials can be identified.

When you do not pick the right material for a diaphragm pump,

the pump may start to leak due to the corrosiveness of the fluids.

There are several systems in the market that can detect the leakage of diaphragms.

A simple and effective method that I have applied is the use of infrared sensors.

You combine these infrared sensors with a PLC that can carry out actions (e.g. stop a pump, give off a warning signal, etc.).

This is ideal when dealing with dangerous fluids, hard-to-reach or dangerous locations, when pumping a costly product,

or when standards require that consistent monitoring is mandatory.

Would you like to know more on materials or how you can make your pumps ‘smart’?

Then please reach out to me by sending me a personal message.

Contact our specialists

We know that every application requires a different approach and every project is a new challenge.

That is why our product specialists will provide you with professional advice and a thorough

understanding of our products.

Call George van de Rijt on + 31 6 224 23879 | Send us an email