Mechanical seals: To replace or to overhaul?

A mechanical seal is an important part of the sealing of pumps and mixers to prevent the medium from entering the atmosphere.

Even when used correctly, your mechanical seal will wear out over time and possibly even begin to leak.

This may be due to various causes, such as wear, worn sliding surfaces, cavitation or dry running of the pump, or the failure of bearings. This could have serious consequences and, in extreme cases, bring a halt to production. However, none of this is necessarily a reason to replace the mechanical seal with an entirely new seal.

To avoid production being halted—or worse scenarios—there are a number of possible solutions. You could consider the

replacement of the mechanical seal. However, this

is not only time-consuming, but is also a very costly option.

There are other cost-effective solutions besides replacing your mechanical seals, namely overhaul or partial replacement and

overhaul. The overhaul of a mechanical seal can save you 40% of the cost of purchasing a new mechanical seal, and it will last

just as long as a new one!

What is an overhaul?

During an overhaul, a search is performed to look for any "faults" and for options to extend the service life by making small

adjustments.

Tip: Have your mechanical seals and distribution discs overhauled by a specialist. ERIKS can do this for you: The ERIKS Repair

Centre overhauls more than 5000 seals per year, giving us the know-how necessary to work on your seals. The Repair Centre is also

ISO 9002-certified.

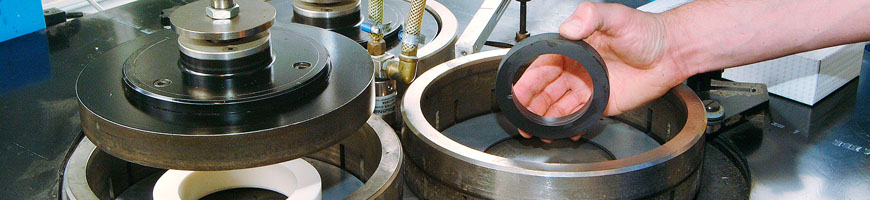

Our workshop measures 240m² and, equipped with all the latest production, inspection and test tools, is one of the best-equipped

repair centres available. This allows us to overhaul mechanical seals from all renowned manufacturers under optimum conditions.

This includes mixer/reactor seals, cartridge seals and the more expensive single springs.

All processes — disassembling, cleaning,

lapping, inspection and installation—are performed in a specially designed and designated space.

Would you like your mechanical seal overhauled at the ERIKS Repair Centre? The overhaul of a mechanical seal is performed using a

number of processes.

You can read more about the different processes involved in the overhaul of a mechanical seal below:

- The seals are given an initial inspection and a unique location within the workshop.

- After the inspection, the mechanical seal is disassembled.

- The parts are then cleaned using ultrasound.

- After cleaning, the bearing surfaces made of silicon carbide, tungsten carbide and other hard materials are ground and lapped.

- After lapping, the sliding surfaces are checked for flatness using monochrome light and a plan glass. The surface roughness is also checked.

- After the check, we will produce specifications and a quotation for you.

- Lastly, after the replacement of the elastomers and any other non-reusable parts, the mechanical seal is installed and will once again satisfy the original factory specifications. And all of this at a very attractive price.