The suitable seal for

rotary shafts

Machines contain moving parts. Where these parts move side by side, seals must prevent media from entering and leaving.. This also applies to rotating shafts and rods. Rotating shafts and rods are for example the propeller shaft of a ship, a mixer for dough and other baking products or gears.

A proper seal is required to ensure that, for example, the grease or oil stays on the bearing and dirt stays off the bearing. Which seal is suitable depends on the type of application.

Using an unsuitable seal can cause many problems. In case of leakage, for example, oil or grease can drain away and the bearing can become dry. Conversely, water can enter the sealed application and damage the bearings.

If the seals do not work properly, your system may also become dirty or damaged. A proper seal is therefore necessary. Read on to find out which seals are suitable for your application.

A proper seal per application

Three types of applications can be distinguished, namely: standard applications, demanding applications and food applications. Various seals are suitable for these three applications. This will be explained per application.

Standard applications

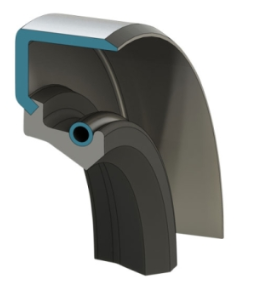

If oil or grease is present on the tread of a seal, a standard oil seal ring is often sufficient. These seals seal in a pressureless condition and are available in NBR and FKM/Viton®. On request, they are also available in other rubber types. The most commonly used seal is made in NBR, with a temperature range of -35°C to +100°C with an average chemical resistance.

For temperatures up to 180°C or higher chemical requirements, FKM should be chosen. When your application is in a clean environment, the most standard types, the ERIKS R and its predecessor type M are sufficient. The ERIKS R and type M are for example used for gearboxes and shaft ends of machines.

If there is dirt involved, the types RST or MST are appropriate. These seals have a dust lip that keeps the dirt away from the sealing lip on the back side, for example gearboxes or shaft ends of machines. If large sizes are used or damage is expected due to difficult installation, the ERIKS GV offers a solution. For example, in ship engines.

Thanks to the double metal casing, type GV is more resistant to heavier mounting and twisting of the metal. It is also possible to produce type GV with dust lip. In this case type GVST is chosen.

Demanding applications

In some applications, the requirements are so high that a standard oil seal is not sufficient. When there is pressure on oil seals, they can be pushed out of their holes. Special pressure seals of type RST-D may be used up to a maximum of 5 to 10 Bar in otherwise ideal conditions (with lubrication, low speed, no high temperature).

If one of these circumstances arises, oil seals can no longer handle it. In that case PTFE lip seals are chosen. PTFE has a temperature range of -90°C to +260°C. The PTFE lip seal has a high resistance and the seals can have a perfect fit up to 10 Bar and on request even up to 25 Bar.

The PTFE also offers a solution for non-lubricated applications. Because PTFE compounds are more resistant to dry running, powders and gases can also be sealed.

Food applications

Since the European directive EC1935/2004 was introduced, seals are increasingly required in the food-safe version. Although ordinary oil seals can be made from food-safe rubber compounds, the design of these rings means that they are not or hardly cleanable, which can cause dirt to accumulate. This is in violation of food legislation.

Ps Seals® are therefore commonly used for food applications.

These are the special PTFE compounds: Gylon Blue, Gylon White and Gylon F and are EC1935/2004 approved.

The design of the Ps Seal® ensures that dirt cannot build up. Moreover, Ps Seals® are easy to clean.. Versions in food-safe compounds are available on request. These Ps Seals® are used for example in dough mixers, blenders, chemical pumps and robot arms.

Not sure which seal is suitable for your application? Please contact us directly. Our specialists are there to help you!

Find a Service Centre | Send us an E-mail