Tips & Tricks for the circulator pump

ERIKS Pump Specialist. George develops pump solutions to reduce the Total Cost of Ownership (TCO) for clients within his industry.

LinkedIn | 06 224 23879

Regularly I visit boiler rooms for clients and I am surprised at incorrect installations that I sometimes find there.

Because I occasionally encounter common errors,

I would like to give you a couple of Tips & Tricks on circulator or HVAC pumps.

Types and brands

There are several types and different brands for circulators or HVAC pumps on the market.

Generally, pump manufacturers make use of the same model specifications.

The model number is built up as follows:

first comes the model name of the pump, followed by the nominal diameter of the suction, then the head and finally the port to port dimensions.

Let’s take the pump type 24-/180 as an example.

This pump has a nominal diameter of 25mm, a head of a maximum of 4 meters and an installation length of 180mm between screw fittings.

Glanded versus non-glanded pumps

A term that we often hear with circulator pumps are ‘wet’ and ‘dry’ pumps. We use these terms because there are two different types of circulator pumps.

In one type, we find that the engine is cooled and the bearings lubricated by the fluid; a glandless type (wet); also known as wet rotor circulators.

In the other type, the engine is cooled by air or fans; a glanded type (dry).

The dry circulator pump has a seal or division between the hydraulic and the electrical part.

Nowadays this is usually done with a mechanical seal.

Assortment circulator pumps

Discover the assortment of circulators or HVAC pumps on the ERIKS webshop and find the right product for your application.

View the assortment

Pump installation

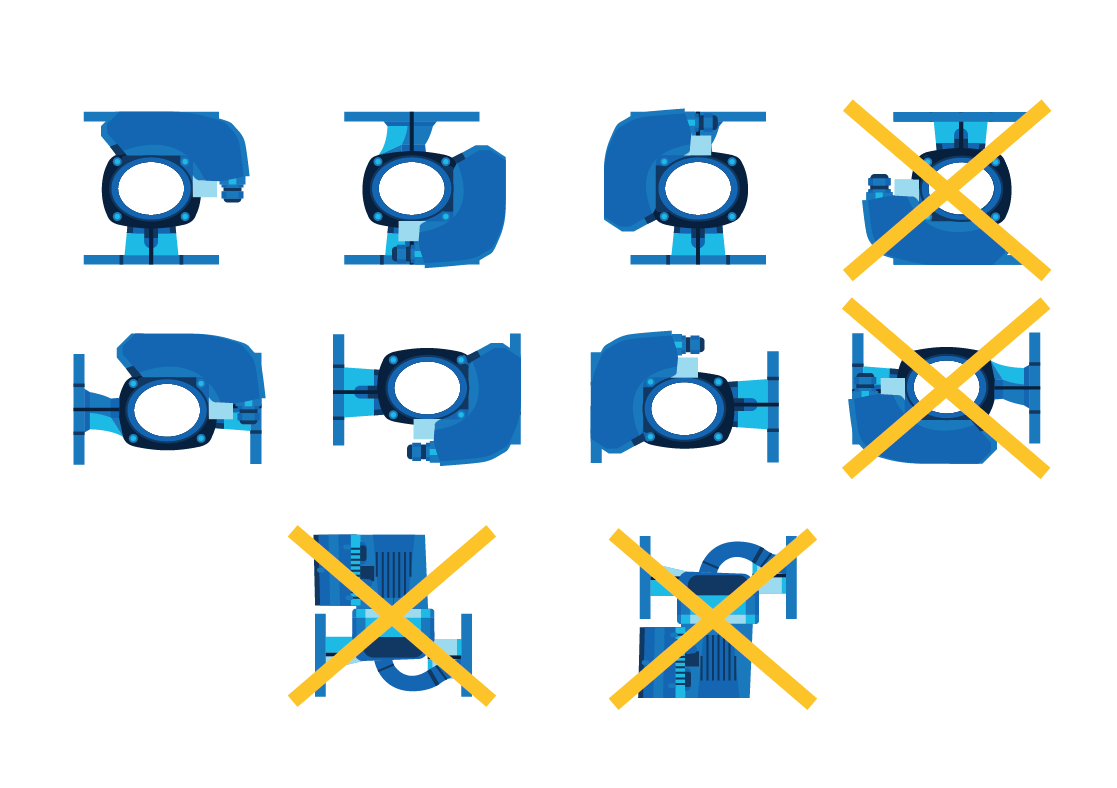

Unfortunately, I occasionally run into pumps that have been installed incorrectly which, in turn,

will cause the pump to fail more quickly. The image below illustrates what you can and cannot do.

Circulator pumps (non-glanded) can be installed into a pipe without the help of a mounting support.

Glanded circulator pumps usually have larger motors.

That is why you must always check the manual to see whether a mounting support is required.

You should also try to place valves in front of and behind the pump so that you can block in the pump for maintenance.

This way you do not have to drain the entire HVAC system.

Replacing pumps: port to port dimensions

There are several manufacturers available who offer handy tools to replace your circulator or HVAC pumps.

Please keep in mind however that some older types cannot be replaced by the same pump type.

Dimensions of old and new types often vary and for those you will need adapters.

Always replace the gasket when a flange connection is used.

Please note that some manufacturers do not supply these replacements with your initial pump.

Replacing pumps: voltage

After the energy standards became stricter,

the circulator pump with a permanent magnet found its way into the market.

Many of these pumps are frequency regulated and run on 230v instead of the ‘old’ 400v pump,

which is usually installed. When replacing a pump, please take note of the voltage involved.

Saving energy

The chance that a circulator pump has been over proportioned is quite high.

When a pump has to replaced this is the ideal moment to fix this issue.

A manufacturer may be able to offer a ‘smaller’ pump if you submit all the details of your current pump.

It would be ideal if details the flow and desired pressure of the pump are available.

Contact our specialists

We know that every application requires a different approach and every project is a new challenge.

That is why our product specialists will provide you with professional advice and a thorough understanding of our products.

Call George van de Rijt on +31 6 22 42 38 79 | Send us an email

Read more on pumps

Various engineering consultancies and manufacturers have analysed pump installations.

Their analysis has shown that there is a range of possible improvements that could result in energy consumption being reduced by 70%.

Read more

Opting for the wrong components or selecting the wrong pump can prevent your pump from performing to its full potential.

Pumps often consume an unnecessarily large amount of energy and show signs of wear. Read more on this case study.

Read more