Ever since its founding, Eriks has always been active in the food industry as a supplier.

Think of dairy products, soft drinks, powders, raw materials up to the processing of vegetables.

In the food industry you must consider different regulations regarding food safety and the material choice of your products, including oil seals.

We have opted to write this article after we have received a lot of questions regarding which oilseal would be best for your application.

We would like to inform you which regulations to consider, what happens when an oil seal does not meet these requirements and what services we can provide to help you.

Why should an oil seal meet food requirements?

An oil seal is used when you want to prevent foodstuff from entering through the rotating axle,

but also to prevent external dirt and water from contaminating the foodstuff.

Because the oil seal lip comes in contact with the foodstuff, it cannot contain elements that:

- Are hazardous for people's health

- Could lead to an unacceptable change in the composition of the foodstuff

- Could lead to a contamination of the organoleptic properties of the foodstuff

These requirements for the Food Contact Materials (FMC) regulations have been recorded in article 3 of the EC 1935/2004.

This law has come into effect since April 1st 2009 and its compliance thereof is checked in the Netherlands by the Netherlands food and consumer product safety authority (NVWA).

Other than the EC 1935/2004, there is also the regulation of the FDA (Food and Drug Administration) of the United States.

An oil seal that has been FDA approved does not automatically satisfy the requirements set by European law.

Assortiment oil seals

Discover the assortment of oil seals on the ERIKS webshop and find the right product for your application.

View the assortment

Why doesn't a standard oil seal meet the requirements set by the FDA or the EC 1935/2004?

Since the implementation of the EC 1935/2004 regulation the requests for foodsafe oilseals have steadily increased.

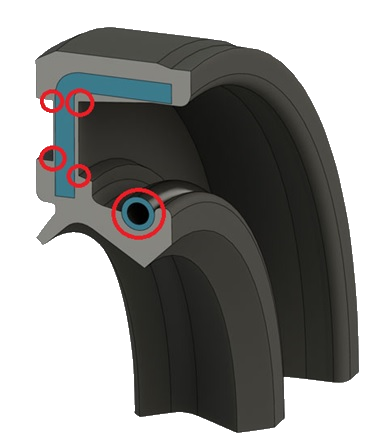

Though oil seals can be made with food safe rubber compounds, it is still quite common that these seals are difficult to clean or cannot be cleaned entirely.

This causes a build-up of dirt which can contaminate the foodstuff and is therefore not in line with the food safety regulations.

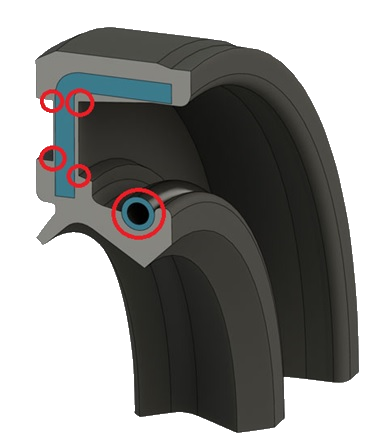

The image below shows you in which areas dirt can accumulate.

This accummulation can start to rot, which carries damaging and negative consequences for the final product of a consumer.

PS Seals® are therefore regularly used for food applications; these are special PFTE seals: Gylon Blue,

Gylon White,

Gylon F

and Gylon Brown/White.

Dirt cannot accumulate due to the design of the PS Seals® and they can also be properly cleaned.

In addition, these seals are all EC 1935/2004 approved.

You will find these PS Seals® in dough mixers, blenders, chemical pumps and robot arms.

Food safe editions of oil seals are always available on request at ERIKS.

Selecting a seal that does not comply with food regulations

When you select an oil seal that does not comply with either the EC 1935/2004 or FDA regulations,

then the seal might break. The pieces that break off will then find their way into the final product.

This is not advisable because this can be dangerous for the customer.

The Netherlands food and consumer product safety authority

therefore takes immediate action against violations and hands out severe sanctions should these regulations not be followed.

Not only is choosing the right seal important for the food safety of your products, but the right choice also saves you time and money.

How can we help you make the right choice?

ERIKS offers a variety of possibilities in delivering seals that comply with the food safety regulations.

For example, we also offer materials that are suitable for a dry axle.

Every application deserves its own approach. Therefore we would like tyo advise you to get in contact with us for free advice.

You may contact us through phone or per e-mail via the contact details described below.

Contact our specialists

We know that every application requires a different approach and every project is a new challenge.

That is why our product specialists will provide you with professional advice and a thorough understanding of our product

Call us at +31 (0)72 514 18 55 | or e-mail us OKHY@ERIKS.nl

Read more about seals

One of the most common seals in technology is the oil seal.

These are typically applied as a seal without help from a lubricating oil and grease on a rotating axle. These tips will help you with your selection.

Read more

There are different types of oil seals that fit a different application and surroundings and are made out of different materials.

The right material and type of oil seal is determined by the application and the medium that will be used with the oil seal.

Read more