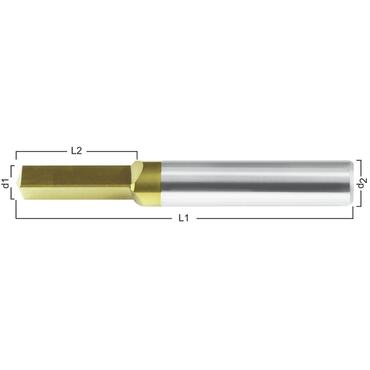

FORMAT Stud extractor type 1854

Product documents

| Document | Document type |

|---|---|

| Product overview |

Design: Solid carbide, type N. The Tap borer has 3 blades.

Application: Extraction must take place dry at ca. 1500?3500 rpm. With use of the right tap bore-out tool, the core of the tap is quickly bored out and the rest of the tap can be cleanly blown out of the drill hole. The workpiece must be clamped very steadily so that movement does not happen at higher speeds. A centring must be produced first by starting the tap bore-out tool up several times if the tap has broken off at an angle. Boring out can only be started now. Furthermore, the chips should be removed by "air blow" several times.

A vibration can be felt just before the end of the bore-out process. The extractor should now be removed.

The new thread can then be cut with a tap. Due to the high stresses caused by boring out, the cutting edges of the tap bore-out tool need to be resharpened from time to time.