Head Protection Equipment:

Safety Helmets & Bump Caps

According to statistics from Eurostat, head injuries account for 198.789 of all non-fatal work-related accidents and 789 of all fatal work-related accidents. These numbers could be lower if workers within the sectors with higher risks of head injuries would wear PPE.

Proper head protection is a must while working in certain surroundings, yet workers sometimes forget to wear a helmet or bump cap. Accidents involving

potentially serious head injuries can happen very quickly and can have long-lasting effects on one’s health, such as brain aneurysms and haemorrhages.

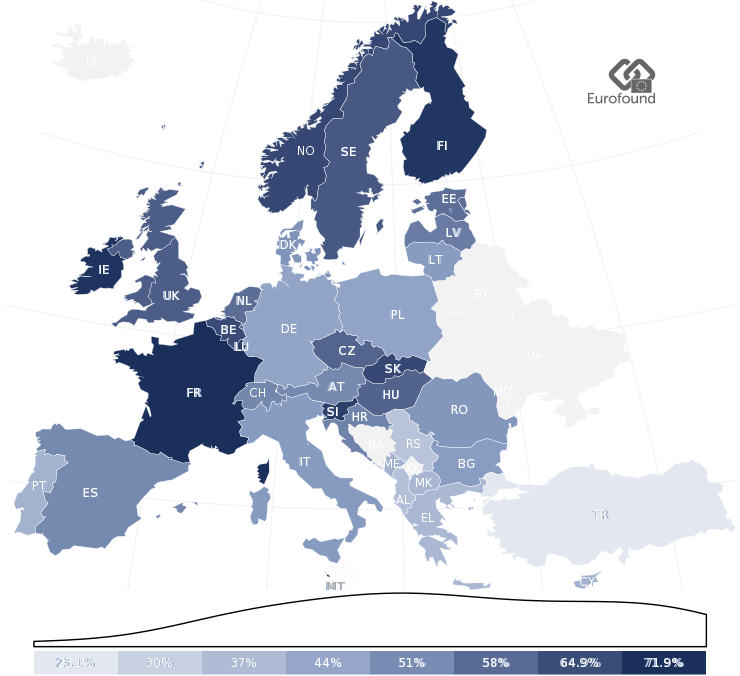

In 2015, the European Commission conducted a survey about working conditions where they asked several questions about the working environment within the EU28.

The participants of the survey were asked if their job ever requires to wear personal protective equipment (PPE) and if they do so. Most workers within the

sector agriculture and industry answered that PPE is not required.

The percentage of workers that are required to use and actually do use PPE in Germany (26%) and Switzerland (29%) is in comparison rather low, while in

France (40%), Great Britain (43%), the Netherlands (36%) and Belgium (37%) it is relatively high. The average percentage of workers that are required to

use PPE but don’t use it lies between 2% and 4%.

These statistics show how exposed workers are to accidents and injuries at work, and how important it is for employers to provide their employees with

the proper personal protection equipment to prevent or minimize injuries in the workplace.

All employees working in areas where there is a possible danger of head injury from impact, falling flying objects or electrical shock and burns should

be protected by safety helmets. Protective helmets should be worn during most construction works, works with lifting equipment and suspended loads, forestry,

wells, shafts or tunnels. In all these situations the use of PPE will protect against injuries to the scalp and skull.

1. Basic safety rules for head protection

Head protection is one of the most frequently used pieces of personal protective equipment (PPE). It protects the user’s head against:

- Impact from falling objects from above, through resisting and deflecting knocks on the head,

- Hitting fixed and dangerous objects at the workplace,

- Lateral forces - depending on the type of the hard hat,

- Open flames, molten metal splashes, electric shocks and high temperature

Regardless of the type of head protection worn, one should follow the recommendations below when adjusting and positioning the head safety equipment:

- The harness that crosses the top of the helmet has to adhere closely to the head.

- The headband that runs around the head should adhere strictly to the forehead and back of the neck.

- The safety helmet should be securely mounted on the head. The helmet’s movement should be limited by the minimum amount of clearance between the hard shell and the skull, in order to provide balance and a low center of gravity.

- The helmet should be adjusted in such a way that even without the use of a chin strap it will stay on the head without falling.

As for the type of material most suitable, this depends on the PPE worn and on the type of hazard expected. For example, a soft foam can absorb smaller shock loads, such as impacts from a projectile or a ball, and return to its original shape for further use. On the other hand, larger shock loads will require a non-elastic harder foam, which will not return following impact.

Explore our full assortment of safety helmets, bump caps and accessories from top brands like HONEYWELL, THORMAS and CENTURION.

See the assortment2. Types of head protection equipment

Head protection equipment can be classified into two main types: safety helmets and bump caps. We'll discuss each of them individually below.

Safety helmets

Safety helmets or hard hats are meant to absorb the force of blows and can be fitted with ear defenders and visors. In case of a blow, the shell and

protective padding inside the helmet will absorb the shock and will be partially damaged or destructed. Just like other PPE, safety helmets need to

comply with European norms or equivalent national standards, and must be marked accordingly, inside the shell.

For selecting the right piece of protection equipment, one should know the types and industrial classes that hard hats are divided into. There are two main

types of safety helmets:

- Type 1 includes helmets with full brim, which are intended to reduce the force of impact resulting from blows to the top of the head.

- Type 2 includes brimless helmets with a peak that extends forward from the crown. These are intended to reduce the force of lateral impacts resulting from blows which may be received from the side or to the top of the head.

As for the industrial classes, hard hats are divided into three classes:

- Class G (formerly class A) includes general service helmets that offer limited voltage protection (up to 2.200 volts phase to ground).

- Class E (formerly class B) includes helmets for electrical work and utility service, which offer protection against exposed high-voltage electrical conductors up to 20.000 volts (phase to ground).

- Class C includes helmets that don’t offer electrical protection and are often electrically conductive.

A wide range of accessories can be fitted to helmets to make them more suitable for variable working conditions. Examples include a retaining strap worn

under the chin or at the nape of the neck or a bracket and cable clip for the attachment of a lamp.

Also, eye or face shields, wide brims for additional shade in hot climates, neck flaps for protection against weather or molten metal splash and additional

lining for cold conditions are examples of accessories that can be added to hard hats.

Care should be taken to ensure that accessories and their attachment systems do not reduce the safety characteristics of the helmet nor adversely affect

the balance or comfort of the helmet.

Our recommended products |

||

|

|

|

| CENTURION Nexus Heightmaster safety helmet with ratchet white | THORMAS Hard Hat TSSH-CR1 Full Peak Opaque Rim White | HONEYWELL Face shield Set VDE-visor/helmet A-79 |

| ERIKS item #: 13035275 | ERIKS item #: 13311133 | ERIKS item #: 23307333 |

| Buy now | Buy now | Buy now |

Bump caps

Bump caps are designed for low-impact hits and don’t provide the same level of protection as helmets, therefore shouldn’t be worn as a replacement for safety helmets. They come

in the shape of plastic shields designed to fit inside uniform baseball caps, so they’re more comfortable to wear. For this reason, some workers in hard hat zones might

prefer to use the bump caps instead of helmets.

Industrial bump caps have the following advantages:

- Avoid the pressure that is caused by a harness and the headband

- Bump caps are lighter than safety helmets and thus is the weight on the neck muscles less

- The ventilation is better with bump caps, which is especially hard whilst doing hard physical work or when working in high temperatures

With a plastic insert lower kinetic energy can be absorbed and dissipated. At higher impact energy of objects or high temperatures, only a safety helmet provides sufficient security. Keep in mind that both these PPE are meant to protect the head, but they offer no protection for the neck or spine. Therefore, when performing work at height for example, workers shouldn’t rely only on safety helmets, but should wear proper PPE for work at height.

Our recommended products |

||

|

|

|

| CENTURION Bump cap white | CENTURION Cap AirPro SecurePlus blue reduced peak | HONEYWELL Pet Proficap dark |

| ERIKS item #: 12523171 | ERIKS item #: 13425136 | ERIKS item #: 23307609 |

| Buy now | Buy now | Buy now |

3. Construction and markings on safety helmets

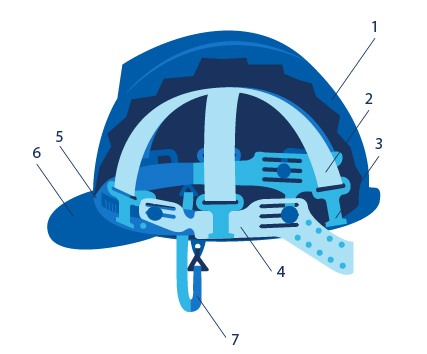

Regardless of the manufacturer, safety helmets have a similar construction, which may look like below.

In this example, the different parts of the hard hat are:

- Shell: rigid outer section of the helmet

- Harness: internal part of the helmet (fastened to the inside of the shell)

- Harness fixing

- Headband: contours the head around the forehead and the skull, allows for a stable positioning of the helmet on the wearer’s head, it is equipped with adjustment mechanisms

- Sweatband: can often be found in safety helmets, to absorb sweat

- Peak/Visor

- Chinstrap:to keep the hat in place

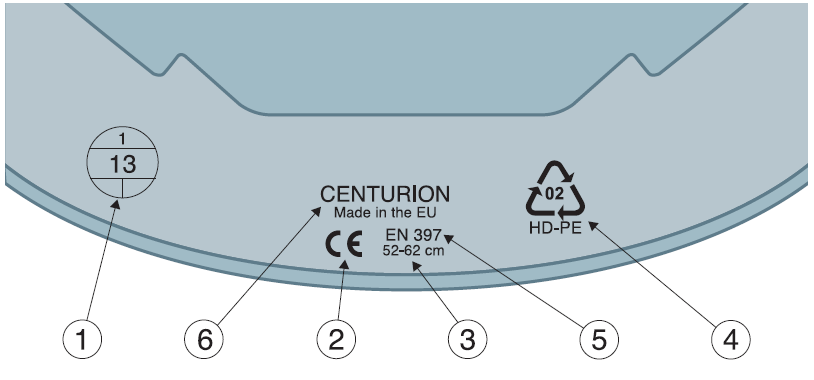

Inside the shell there should be details regarding the manufacturing date, size, protection offered and type or class of helmet, as you can see below. EN 397 requires that at least the following information must be marked on the inside of the helmet shell:

- 1. Month and year of manufacture

- 2. CE Marking

- 3. Size

- 4. Material characteristics

- 5. Standard

- 6. Manufacturer

A helmet which offers additional protective features may also have a label on the shell with information regarding:

| 20 °C / -30 °C / -40 °C | Very low temperature |

| +150 °C | Very high temperature |

| 440 V AC | Electrical resistance: provides protection against live current conductors in case of accidental contact with the helmet up to the specified voltage limit. |

| MM | Molten metal: guarantees that there is no penetration of liquid metal splashes, indicating a quality-heat-resistant scale. |

| LD | Lateral deformation: offers protection against lateral pressure and shows the improved lateral strength of the helmet. |

| 1000 V | Applications up to 1000 V AC. |

| Double triangle + class 0 + serial or batch number | Tested according to EN 50365 for use near 1000 V AC (class 0). |

| Image of an acorn | German characteristic for forestry. |

In what concerns the materials used in the construction of hard hats, these may vary per producer, but again, there are some standard materials used in safety helmets.

ABS (Acrylonitrile Butadiene Styrene): is a copolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. ABS is impact resistant and tough and

can withstand a temperature range from -40° C to 100° C.

HDPE (Hi-Density Polyethylene): a thermoplastic HDPE has a stronger intermolecular force and tensile strength than lower-density polyethylene. It is also harder and more opaque

and can withstand higher temperatures (120° C for short periods, 110°C continuously).

PC (Polycarbonate): A particular group of thermoplastic polymers, temperature resistance, impact resistance and optical properties. Although polycarbonate is impact resistant,

it has a low scratch resistance. PC maintains its properties over a wide range of temperatures (from -40° to 115° C).

PP (Polypropylene): A thermoplastic polymer, normally tough, flexible and with a good resistance to fatigue. The melting point is at approximately 160° C.

Fiberglass (fiberglass and phenolic-impregnated textiles): Thermoset is material made from extremely fine fibers of glass. Properly known as fiber-reinforced polymer (FRP) or

glass-reinforced plastic (GRP). It has no true melting point but softens at 2.000° C.

4. Standards and regulations

The European Framework Directive on Safety and Health at Work (Directive 89/391 EEC) was adopted in 1989 and was a substantial milestone in

improving safety and health at work. The framework guarantees minimum safety and health requirements throughout the European Union while Member

States are allowed to maintain or introduce tougher measures.

These are the essential norms concerning head protection:

- EN 14052: High performance industrial helmets

- EN 397: Safety helmets

- EN 812: Bump caps

- EN 50365: Insulating helmets for use on low voltage installations (1500 V (DC) or 1000 V (AC))

- EN 12492: Helmets for mountaineers

- EN 443: Helmets for firefighters

The most relevant standards are EN 397, EN 812 and EN 14052, which will be described in more detail here.

EN 397 – Industrial Safety Helmets

EN 397 requires that safety helmets must be designed to protect the wearer from falling and against sharp and pointed objects. For a safety helmet that meets the shock

absorption requirements of EN 397, the maximum transmitted force cannot exceed 5 kN.

To test the compliance with EN 397, the helmet is placed on a suitably sized and

dimensioned headform that is mounted on top of a load cell on a rigid base. Then, a striker (with a hemispherical surface of suitable mass of 5 kg) is dropped onto the

helmet from a height of 1 metre.

The test for the penetration requirements of EN 397 is similar: a striker is dropped from a certain height onto the helmet that is fitted to a fixed headform. But in this

case the striker is a pointed cone (3 kg heavy and dropped from a height of 1 metre), and rather than measure the transmitted force, the assessment is based on whether the

striker makes contact with the headform underneath the helmet.

This test can be done by using indicator material (plasticine or soft metal) on the headform itself, or by

creating electrical contact between the striker and headform. If the striker contacts the headform, a circuit is established which sets off an alarm.

Helmets can only offer full protection when they are retained on the head through a chin strap. Therefore the chin strap anchorage has also to be tested to comply with EN 397:

the chinstrap must have a minimum width of 10 mm when untensioned and must be attached to the shell or to the headband.

The strength of the strap anchorage should be enough

to hold the helmet on the head but should not strangulate the wearer. A force is applied to an artificial jaw at a rate of 20N/min until the artificial jaw is released, due

to failure only of the anchorage. EN 397 requires that the force at which this occurs shall be minimum 150 N and maximum 250 N.

Industrial safety helmets that comply with standard DIN EN 397 should meet the following safety requirements:

| Binding requirements | Optional requirements |

|

|

EN 14052 – High Performance Industrial Helmets

Helmets that comply with the norm EN 14052 have to protect the wearer against falling objects and lateral impact along with the resulting damage to the brain, skull and neck.

The tests that are carried out to assess the shock absorption for EN 14052 are similar to that used by EN 397 but with a significantly higher impact energy and the impacts

are carried out on both crown and front, sides and the rear of the helmet.

The impacts on the crown have an impact energy of 100 J (this is a mass of 5 kg dropped from roughly 2,04 metres)

and off-crown impacts with an energy of 50 J (5 kg dropped from approximately 1,02 metres) while the headform is inclined at angles of 15°, 30°, 45° and 60°.

Concerning the penetration test, the conical striker used for the EN 397 testing is replaced with a flat blade striker (which is also used for the EN 443 testing - firefighter helmets).

The blade striker weighs 1 kg and is dropped onto the helmet from a height of 2,5 metres for crown impacts and from 2 metres for off-crown impacts - with no contact between the striker

and the headform being allowed.

This type of helmet is more stably fitted on the head so that it can prevent the helmet from falling when an impact occurs. This additional stability is achieved through the headband,

the chinstrap and the shell that is made from thicker or harder materials. Despite of the higher security and additional protection, these helmets are heavier than usual safety

helmets which can be bothersome for certain types of work.

| Binding requirements | Optional requirements |

|

|

EN 812 – Industrial Bump Caps

Industrial bump caps are intended to provide protection against the effects of striking his head against hard, static objects with sufficient severity to

cause laceration or other superficial injuries, like walking into low ceilings or hanging obstructions They are not intended to provide protection against

the effects of falling or thrown objects, moving or suspended loads.

The test for EN 812 uses a lower energy level than the requirement tests for EN 397: a 5 kg flat striker is dropped onto the helmet from a height of 250 mm,

with a maximum transmitted force of 15 kN. The test is carried out at the front and the rear of the cap with the headform tilted at 30° and 60° to reflect

the nature of any impacts likely in use.

A penetration test is also required for bump caps because they are intended to provide protection against sharp and pointed objects (like corners). The

difference to the EN 397 test is here that the cone is pointed and that the test is based on whether the striker makes contact with the headform underneath

the helmet. Also the shock absorption uses a lower energy level.

EN 50365: Insulating helmets for use on low voltage installations (1500 V (DC) or 1000 V (AC))

These safety helmets are used in environments with high voltage electrical potential (up to 1000 V AC or 1500 V DC).

This standard exceeds the requirements of the optional electrical resistance tests of EN 397 and EN 812.

The test method is similar to these norms: the helmet shell is filled with water and is then put in a tank of water.

Electrodes are placed in the water on the inside and the outside of the shell and a potential of 5000 V (proof test)

or 10.000 V (withstand test) is applied. In the withstand test the current passing cannot exceed 3.5. mA.

Obligatory requirements:

- All helmets must also meet the requirements in accordance with EN 397.

- Protection against alternating voltage of up to 1000 V (AC) or direct voltage up to 1500 V (DC)

- Insulating helmets must not contain any conductive parts.

- Air vents (if available) must not allow any accidental contact with live parts.

Maintenance and replacement of head protection equipment

A crucial and often neglected safety aspect is that both protective helmets and bump caps have a shelf life. In use,

this term is around 2 years, but if a hard hat or a bump cap is subjected to impact, it must be replaced even if there’s

no visible sign of damage.

As for unused head PPE, when stored properly, the shelf life can be up to 5 years. The manufacturing date must be marked

inside the helmet by the producer, and should be checked before using a product.

A safety helmet lasts the longest if it is stored in its original packaging and is not exposed to direct sunlight and heat.

In general, the manufacturer puts the date of expiry date on the head protection. This should not be confused with the date

of manufacturing that is an obligatory requirement by EN 397.

Before using a helmet, it must be fitted to the wearer’s head by properly adjusting it - the headband, the height of earing

and the length of the chinstrap if there is one. The construction of the helmet should not be modified by the user.

Also, one should always look for signs that indicate the head protection will no longer give you the level of protection you need.

If the safety hat is fading, chalky or brittle, it should be replaced. Safety hats that are dented, cut, deeply scuffed or have

been subjected to serious impact should also be replaced.

It is recommended that safety helmets are cleaned regularly. In general, normal washing methods using warm water and soap are adequate.

The use of solvents, very hot water, or harsh abrasives is not recommended. Cleaning and disinfection are particularly important if the

wearer sweats excessively or if more than one person share the same headgear.

Do you have questions about our products?

For personal advise and product knowledge, visit an ERIKS location near you or contact our product specialists.

Find a service center | Call our Customer support | Send us an e-mail