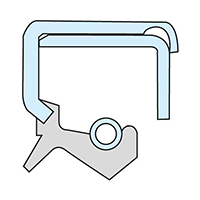

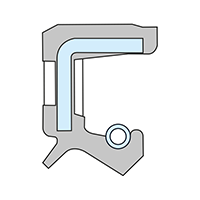

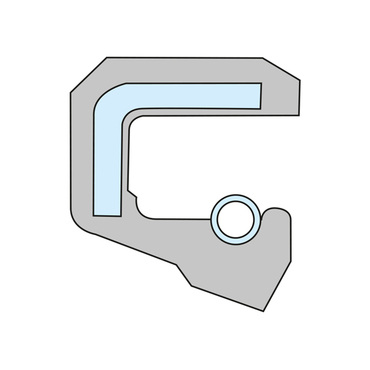

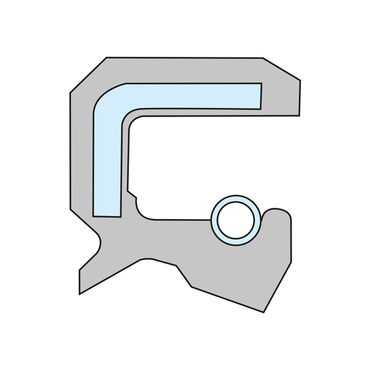

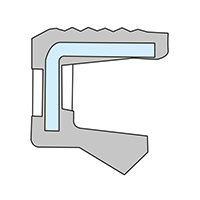

Rubber cased

Rubber-cased oil seals are the most common oil seal execution, used when a metal-cased seal has the potential

to fail. In high temperatures and high pressures, fast expanding rubber can provide a tight fit and more stable sealability. Click on the images below to learn more about the different types of oil

seals.

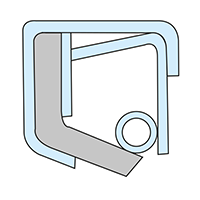

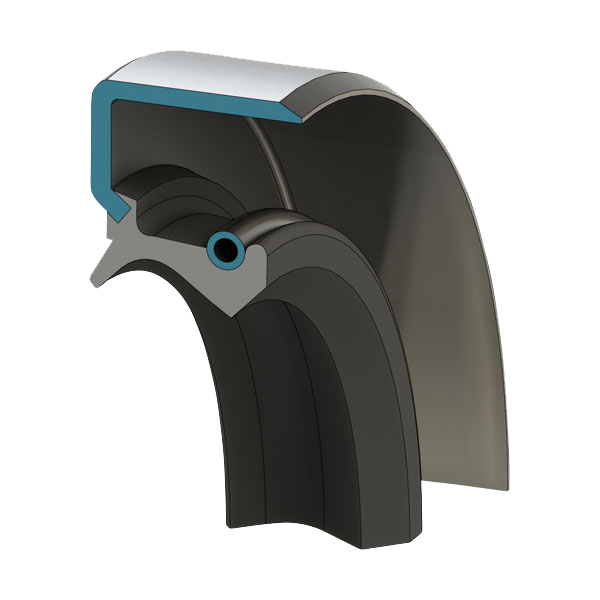

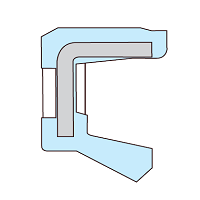

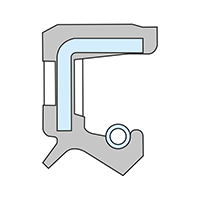

Metal cased

Metal-cased oil seals are used when installed to a housing bore made of the same material. This allows for ...read more

-

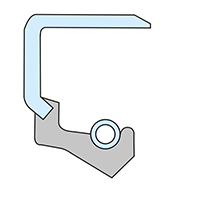

ERIKS Oil Seal type R

-

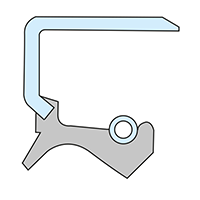

ERIKS Oil Seal type RST

-

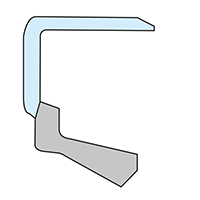

ERIKS Oil Seal type GR

-

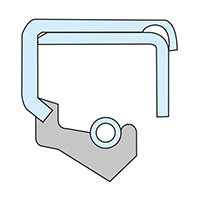

ERIKS Oil Seal type GRST

-

ERIKS Oil Seal type M

-

ERIKS Oil Seal type MST

-

ERIKS Oil Seal type GV

-

ERIKS Oil Seal type GVST

-

ERIKS Oil Seal type GVP

-

ERIKS Oil Seal type GVPST

Oil seals

Of all the types of rotary shaft seals, oil seals, also referred to as Viton oil seals, are the best known. Contrary to what the name suggests, a oil seal is also often used in applications involving a medium other than oil. These seals are sometimes called Simmering seals, based on a brand name used by Freudenberg.

When purchasing a oil seal, you must always consider the shape and size, and the material used for the product.

Types of oil seal

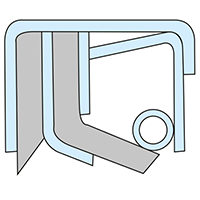

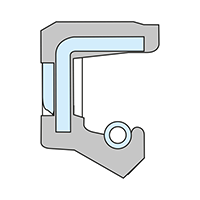

Most oil seals are designed in accordance with the DIN 3760 standard. This standard includes several models. For example, there are oil seals with and without a dust sealing lip. A dust sealing lip prevents dirt ingress from the outside. A useful feature as it reduces contamination in your application, which in turn results in a longer service life.

Oil seal dimensions

Our range includes oil seals in various sizes. Always keep in mind the dimensions of the groove where you will install the oil seal. Once you know the shaft diameter, groove diameter and groove width, you can easily select the right product.

Lip materials

Most oil seals consist of (1) an outer metal jacket, or a metal insert inside a rubber jacket, and a sealing lip. The metal outer jacket or insert acts as a base and determines the shape and size of the product. In most cases, the sealing lip and the jacket or insert are made of different materials. A brief summary of the most popular lip materials and their properties is included below.

- Oil seals with a lip made from NBR

Most sealing lips are made of NBR. This material has many desirable properties. For example, it is highly resistant to various types of hydraulic oil and lubricating oil. However, NBR is not very resistant to ozone, UV radiation and high temperatures (above +120°C).

- Oil seals with a lip made from FKM

FKM, commonly referred to by the brand name Viton, is the sealing lip material to use for applications involving high temperatures (up to +180°C). Furthermore, the standard compounds are resistant to many strong acids and bases, but not to hot water or steam. Only a few special FKM compounds are suitable for applications that involve unusually low temperatures (-40°C or lower).

- Oil seals with a lip made from EPDM

Some sealing lips are made of EPDM, although this is a lot less common than NBR or FKM. EPDM is mainly used for applications involving solvents, hot water and steam. All EPDM sealing lips can withstand low temperatures (down to -50°C) and are resistant to UV radiation. Some compounds are also suitable for high temperatures (up to +150°C).

- Oil seals with a lip made of VMQ

VMQ (silicone) does suit some applications, but is not often used as a material for oil seals. The reason is that VMQ has low mechanical strength, which makes it less suitable for dynamic applications. The material does however withstand both low (-60°C) and high (+200°C) temperatures well. It is also flexible.

Jacket materials

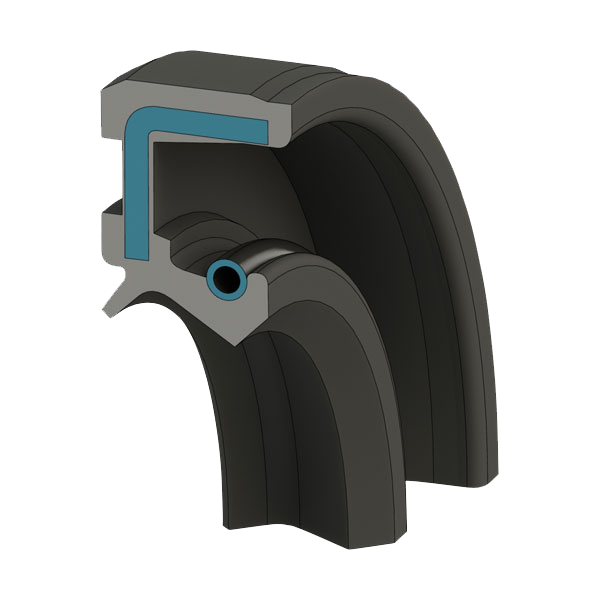

The jacket of a rotary shaft lip seal is made of metal or rubber in most cases.

- Metal exterior

Oil seals with metal outer jackets are often cheaper than those with rubber jackets. They are more difficult to install though. To prevent leakage past the outer jacket, the type of metal used for your oil seal needs to be the same as that of the groove in your application. This avoids a mismatch between the coefficients of expansion. When replacing a oil seal, a product with a rubber jacket may be better in some cases.

- Rubber exterior with a metal insert

As an alternative to a product with a metal outer jacket, you can choose one with a rubber outer jacket and a metal insert. This design is widely used in the maintenance industry because the rubber can accommodate damage or inaccuracies in the groove. Consequently, numerous products with a rubber outer jacket are available.

What if a classical oil seal with a metal or rubber jacket is not what you are looking for? Take a look at our fabric-reinforced oil seals or our PTFE oil seals. These types of oil seals are often used when products with a metal or rubber jacket are not suitable.

Ordering oil seals at ERIKS

What prices does ERIKS charge for oil seals?

The price of our oil seals is shown on the product pages in our online shop. If the price is not immediately visible, it will be displayed after you have logged in.

What delivery times does ERIKS offer for oil seals?

The delivery time for a specific oil seal is indicated on the page for that product. If you need your oil seal sooner, we advise you to choose a suitable alternative. You have three options:

- Choose a wider size that will also fit your application.

- Choose a different material that also works in your application.

- Use our quick-supply solutions, such as the SealXpress service.

What if you have trouble finding a good alternative? Let us help - contact us via the enquiry form.

Can I order custom oil seals?

Do you need to order a oil seal of a different size, shape, colour or material? Or do you need a oil seal for a special application, or one that meets specific certification requirements? Please contact us via the enquiry form and we will provide the support you need.